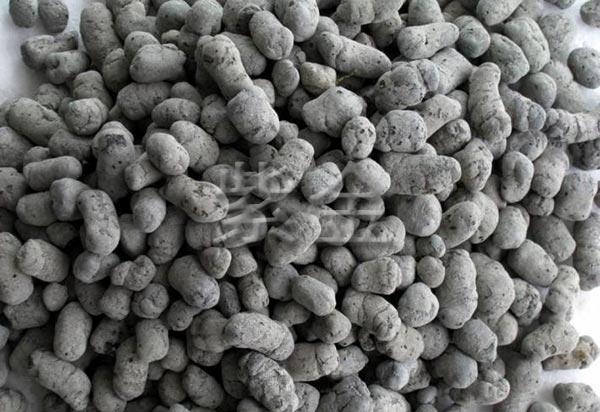

Because of the large amount of voids in the expanded ceramsite, the water can absorb a lot of impurities in the water when the water passes through the ceramsite layer. As a result, the expanded ceramsite is used as a kind of high quality filter material. Its application in filtering mainly has the following aspects.

(1) the application of sewage treatment in China has been a large number of ceramsite used to deal with urban wastewater. Dozens of wastewater treatment plants in China have adopted ceramsite as filtering material, which has achieved satisfactory results. It has the advantages of low filtration cost and high efficiency. The use of ceramsite as a filter medium to purify sewage or to filter other liquids is increasing.

(2) in the application of domestic water filtration, the production of tap water with ceramsite is also a new development in recent years. This is mainly the use of sintering or burning expansion ceramsite to filter domestic water, ceramsite non-toxic, tasteless, good filtration effect, will be more widely used in the future.

(3) in the chemical production filtration process, in the chemical production, there are many products need to produce liquid material or water filtration. In this filtration process, a variety of filters are often required. The use of ceramsite as filter material has the advantages of easy cleaning and repeated use, and is more and more widely used in chemical production. The crushed lightweight sand can also be used as a filter material to replace anthracite - quartz sand double layer filter material. Such as the Chongqing Institute of architecture and engineering have examined the use of surface adsorption ratio for broken type light ceramic sand 0.5-2.5mm open pore rich water filter, used for engineering of industrial water, filtered water can improve the yield of 1-2 times, the technology also has long work period and high quality, the head loss of trapped impurities less etc.. They have made pilot projects in Chengdu and Chongqing, and achieved good results, providing a new approach for the development and utilization of pottery sand. In addition, ceramsite can also be used in the heavy oil dehydration in the petroleum industry.

(4) in food and beverage applications, the water used in the food industry shall be filtered, and ceramsite can be used as a filter aid during the filtration process. In the beverage industry, the use of ceramsite is more extensive, for example, liquor and beer need a large number of filter aid, filter aid will filter the liquor will be clear and transparent. The original filter aid mainly diatomite, etc., and now many manufacturers have used ceramsite as a filter aid. In addition, the production of mineral water and beverage water is also using ceramsite as filter. So ceramsite will also show itself in the food and beverage industry.

(5) in the application of sound-absorbing materials, because ceramsite is porous structure, especially expansion ceramsite, the porosity is higher. These pores can absorb sound waves effectively, so ceramsite has been used to produce sound absorption and sound insulation materials. For example, using it to produce decorative wall panels, sound-absorbing ceiling, and so on, have very satisfactory results. Ceramsite plate, sound absorption frequency range (1200-3000Hz), sound absorption coefficient up to 70%.