In the beginning of the invention and production of ceramic, it is mainly used in the field of building materials, due to the continuous development of technology and people's understanding of the ceramic properties more in-depth application already more than the traditional ceramic materials, expanding the new field of application of it. Now ceramsite in building materials applications, has dropped from 100% to 80%, in other applications, has accounted for 20%. With the continuous development of new uses of ceramsite, its proportion in other fields will gradually increase.

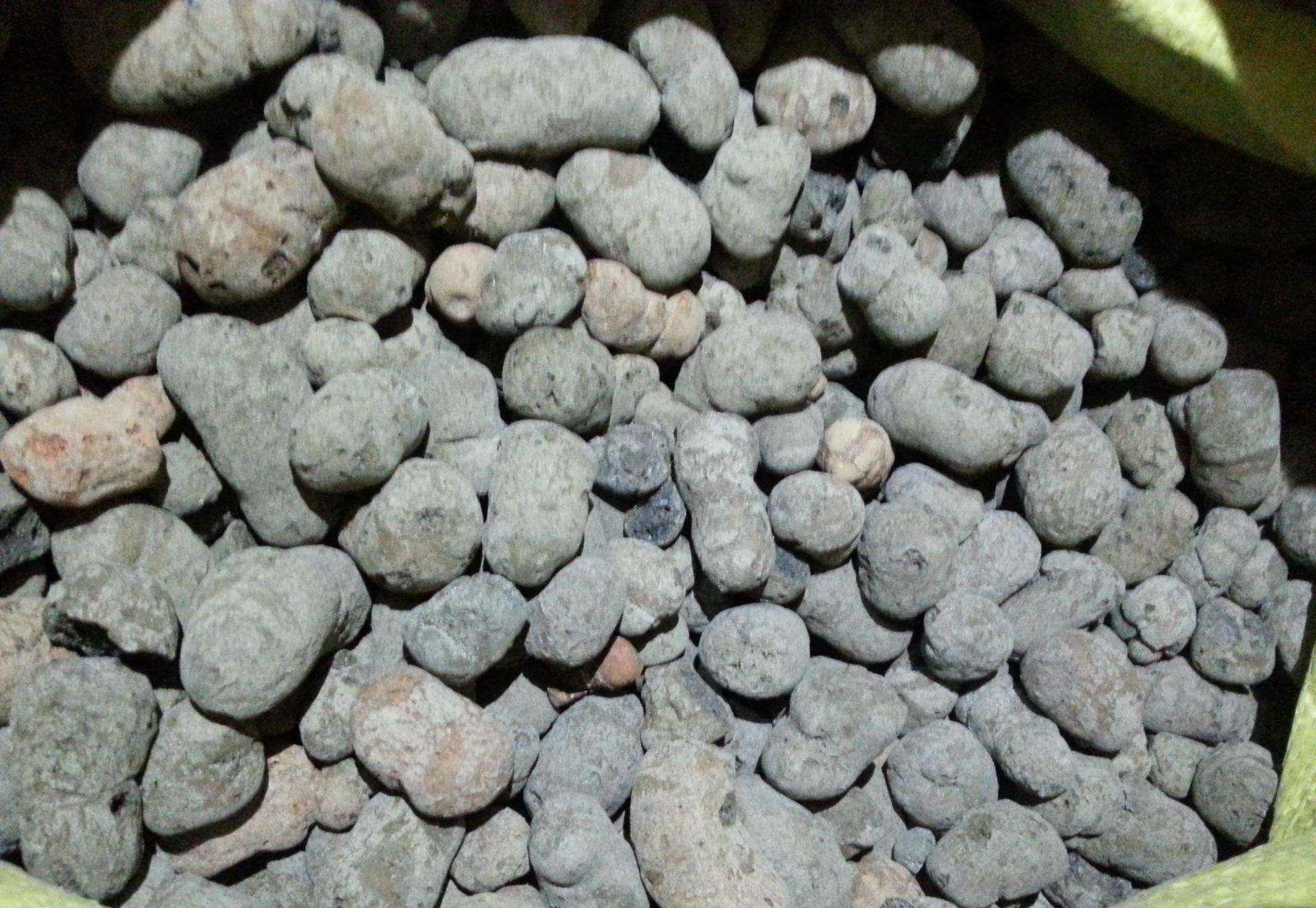

Ceramsite has been developed rapidly all over the world because it has many excellent properties that other materials do not have. This excellent performance makes it have the function that other materials can not replace. Today, domestic ceramsite mainly, but not limited to the application of the following five major areas of application.

One. Thermal insulation building materials

Because the ceramic density is small, the internal porous morphology, with uniform composition, with certain strength and robustness, and has the advantages of light weight, corrosion resistance, frost resistance, earthquake resistance and good insulation and other features, is widely used in ceramic ordinary building roof insulation layer, sloping, Villa / luxury residential properties the floor, non load bearing wall insulation, but also for study, toilet, entertainment and other interior decoration. The application of ceramsite layered water storage drainage system has been widely used in the roof greening and roof greening of underground garage.

Two. Sewage treatment

The ceramsite is spherical particles, uniform particle size, the appearance of red brown, the surface porous pore network with adsorption function arranged in a crisscross pattern, very strong, so the ceramic filter is a kind of advanced water treatment, both for urban and industrial water treatment, also suitable for metallurgy, petroleum, chemical industry, textile industry wastewater the biochemical (oil removal, removal of iron and manganese processing). The advantages of lightweight ceramsite filter materials are: lightweight, loose, small capacity, large specific surface area, high adsorption capacity, high porosity, stable chemical properties, and no harmful components which are harmful to human health and industrial production.

Three, garden flowers

In the landscape because there are many microporous ceramic from the outside to the inside, with certain mechanical strength, water absorption, air permeability, fertilizer retention ability, small particles piled together to form a plurality of holes, air permeability and water, will not harden. No dust under dry condition, the water will not collapse, no mud, this matrix is far better than the nature of the soil. Because of its good air permeability and water than the earth, so the survival rate of flowers is higher than dirt! Total nutrient ceramsite planting soil contains: nitrogen and phosphorus, potassium, calcium, magnesium, sulfur, silicon, iron, boron, manganese, zinc, copper, molybdenum and other nutrients, the survival rate of the plants is higher, the life longer.

Four,refractory materials

High refractoriness is one of the characteristics of ceramsite series. Ceramsite itself is fired by high temperature at about 1400 degrees. The ceramsite concrete is 4 times more common than that of ordinary concrete. For the same refractory period, the sheet thickness of ceramsite concrete is 20% thinner than that of ordinary concrete.

Ceramsite has excellent fire resistance, so it has been widely used in the preparation of refractory castable, and achieved good market results.

Five. Petrochemical industry

Proppant (Tao Lisha) by the high quality bauxite as main raw materials, crushing into fine powder, mixed with various additives, repeated mixing, granulating, polishing, high sintering temperature, the product has high strength, low density, good sphericity, high smoothness, advantages of diversion ability. It is a substitute for natural quartz sand, glass ball, metal ball and other low strength proppant. It has good effect on increasing oil and natural gas. With high fracturing strength, it is mainly used for supporting underground oil fields to increase the yield of petroleum and natural gas. It belongs to environmental protection products. The product can prolong the production period of the fractured oil and gas well, has simple use method, small construction friction resistance, strong seam forming capacity and low cost.